Metal Baler Machine Manufacturer in India

In today’s industrial world, managing and recycling metal waste is becoming increasingly important for businesses in various sectors, from automotive and manufacturing to scrap recycling and metal processing. Efficient waste management not only helps reduce environmental impact but also plays an important role in improving the sustainability of industries. One of the most effective machines designed for compressing and managing metal scrap is the metal baler machine.

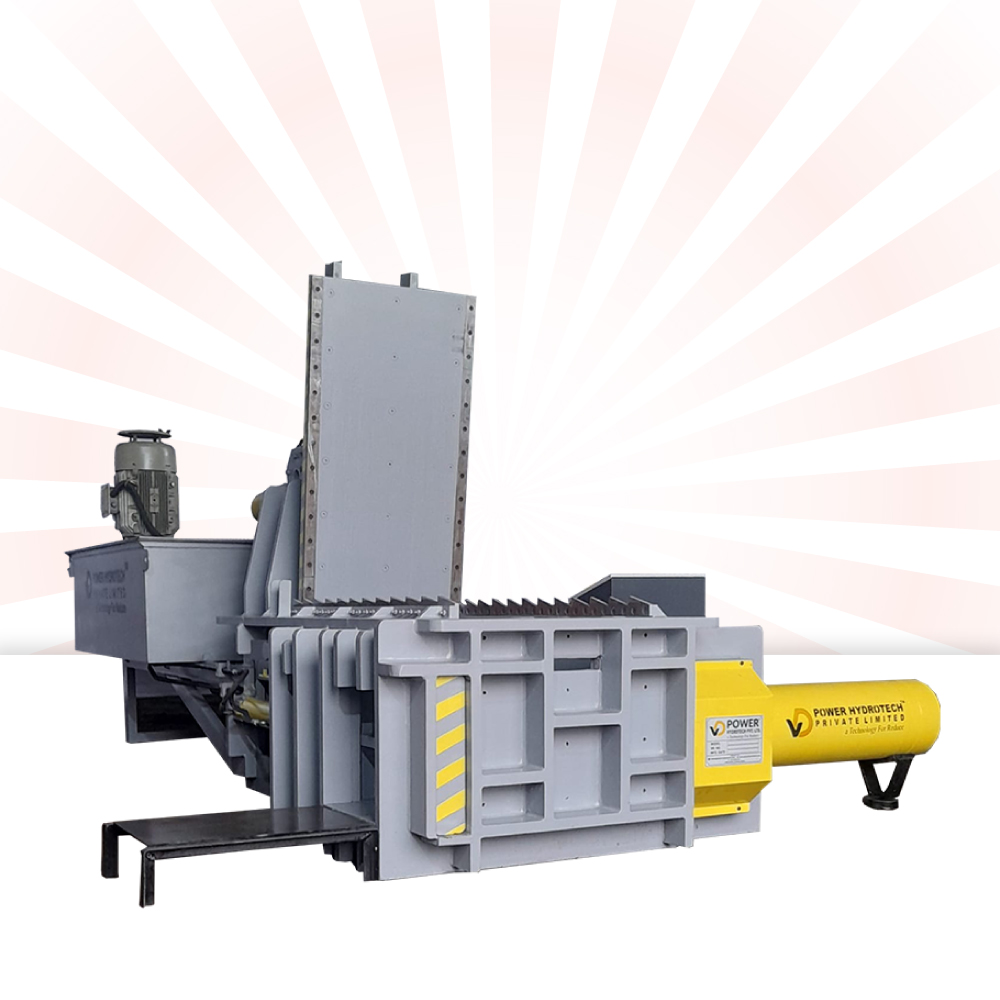

Power Hydrotech, a leading metal baler machine manufacturer in India, specializes in providing high-performance baling solutions that are engineered to handle large volumes of metal waste. These machines are designed to compress metal scrap, whether it’s aluminum, steel, copper, or other metals, into tightly bound bales that are easier to store, handle, and transport.

What is a Metal Baler Machine?

A metal baler machine is a heavy-duty hydraulic machine used for compressing metal waste into compact bales. The machine works by applying hydraulic force to scrap metal, compressing it into a dense, manageable form. This process significantly reduces the volume of metal waste, making it easier for storage, recycling, and transportation. Metal balers are widely used in industries dealing with scrap metal recycling, automotive industries, and manufacturing plants.

The compressed metal bales produced by a metal baler machine can be used as raw material in the production of new metal products, helping to conserve natural resources and reduce the need for mining and extraction. Furthermore, recycling metal scrap through baling increases operational efficiency, reduces landfill waste, and promotes a circular economy.

How Does a Metal Baler Machine Work?

The operation of a metal baler machine is simple, yet highly efficient. Below is a breakdown of how the process typically works:

- Feeding the Metal Waste

The metal scrap, which can include small pieces, discarded metal parts, or larger scrap metal items, is fed into the baler machine. This can be done manually or with the help of a conveyor belt system, depending on the machine setup. - Compression

Once the scrap metal enters the machine, the hydraulic system applies force to compress the metal waste. The machine features a series of hydraulic cylinders that push the metal into a compression chamber, where it is compacted into a tight bale. The compression process ensures that the metal waste is densely packed, reducing its volume significantly. - Bale Formation

After the metal is compressed, it is tied or bound together, typically using steel wire or strapping, to keep the bale intact. The size and weight of the bale depend on the machine settings and the type of metal being processed. - Ejection

The final compressed bale is ejected from the baler machine. These bales are now ready for storage, transportation, or direct recycling. The compacted metal bales take up much less space than loose scrap metal, making them easier to handle and transport to recycling facilities or manufacturers.

Key Benefits of Metal Baler Machines

The metal baler machine offers a range of benefits that make it an essential tool for industries dealing with metal scrap. Some of the key benefits include:

- Space Efficiency

One of the most significant advantages of using a metal baler machine is its ability to save space. Metal scrap can take up a large amount of floor space in warehouses and recycling facilities. By compressing the metal into compact bales, the metal baler machine reduces the volume of scrap, making it easier to store and manage. - Reduced Transportation Costs

Transporting loose metal scrap can be expensive and inefficient. By compressing the scrap into compact bales, a metal baler machine significantly reduces the amount of space the metal takes up. This makes transportation more cost-effective, as more material can be transported at once, reducing the number of trips needed. - Increased Recycling Efficiency

Recycling facilities benefit greatly from the use of metal baler machines. The compressed bales are much easier to handle and process, allowing for more efficient recycling. Additionally, recycling metal reduces the need for extracting raw materials, helping conserve natural resources and minimize environmental impact. - Improved Safety

Loose metal scrap can pose a safety risk in a production or recycling environment. Sharp edges, uneven surfaces, and irregularly sized metal pieces can cause injuries or accidents. By compacting the metal into uniform bales, metal baler machines make it safer for workers to handle the material, reducing the risk of accidents and injuries. - Cost-Effectiveness

Investing in a metal baler machine can result in significant cost savings for businesses. The machine helps reduce storage and transportation costs, while also improving the efficiency of metal recycling processes. By streamlining operations and increasing productivity, businesses can maximize profitability.

Types of Metal Baler Machines

There are different types of metal baler machines available, depending on the specific needs of the business. Some of the common types include:

- Vertical Metal Balers

Vertical metal baler machines are designed to compress metal scrap in a vertical orientation. These machines are typically used for smaller volumes of scrap and are ideal for facilities with limited space. Vertical balers are compact, easy to use, and efficient for processing metal scrap such as aluminum, copper, and steel. - Horizontal Metal Balers

Horizontal metal baler machines are stronger and capable of handling larger volumes of metal scrap. These balers are commonly used in larger recycling facilities and manufacturing plants where high production volumes are common. Horizontal balers are designed for continuous operation, making them suitable for processing a variety of metal waste. - Heavy-Duty Metal Balers

Heavy-duty metal balers are designed to handle the most demanding tasks, processing large quantities of heavy scrap metal. These machines are equipped with high-powered hydraulic systems and strong components to handle larger and more complex pieces of scrap metal. They are ideal for industries that deal with large-scale metal recycling, such as the automotive and manufacturing industries.

Applications of Metal Baler Machines

Metal baler machines have a wide range of applications across various industries. Some of the most common applications include:

- Scrap Metal Recycling

The primary application of metal baler machines is in the recycling of scrap metal. The machine compacts the metal into bales that can be easily transported to recycling facilities, where the metal is melted down and reused in the production of new products. - Automotive Industry

The automotive industry generates large amounts of metal scrap from vehicle parts, such as chassis, body panels, and engine components. Metal baler machines are commonly used in automotive manufacturing plants to compress and recycle this scrap metal, making sure that it is processed efficiently and responsibly. - Steel and Aluminum Production

Steel and aluminum manufacturing plants use metal baler machines to handle scrap metal generated during production. The compressed bales can be used as raw material in the manufacturing of new steel or aluminum products, reducing the need for fresh raw materials. - Demolition and Construction

Construction and demolition projects often generate large amounts of scrap metal, including steel beams, rebar, and other materials. Metal baler machines help compress and manage this waste, making it easier to transport and recycle.

Why Choose Power Hydrotech for Your Metal Baler Machine Needs?

Power Hydrotech is a trusted name in the metal baler machine manufacturing industry. Our machines are known for their high quality, durability, and performance. Here’s why you should choose Power Hydrotech for your metal baling needs:

- High-Performance Machines

Our metal baler machines are engineered for efficiency, capable of handling a wide variety of metal scrap, including aluminum, steel, copper, and more. They are designed to compress metal waste quickly and effectively, improving operational efficiency. - Customizable Solutions

We understand that every business has unique requirements. That’s why we offer customizable metal baler machines that can be adjusted to meet the specific needs of your business. Whether you need a vertical or horizontal baler, we have the right solution for you. - Low Maintenance

Power Hydrotech’s metal baler machines are designed for durability and low maintenance. With strong components and advanced hydraulic systems, these machines require minimal upkeep, reducing downtime and maintenance costs. - Environmentally Friendly

By promoting the recycling of scrap metal, our metal baler machines help businesses contribute to environmental sustainability. Our machines make it easier to recycle metal waste, conserving natural resources and reducing landfill waste.

Conclusion

The use of metal baler machines is essential for industries involved in scrap metal recycling and metal processing. These machines help businesses reduce waste, improve operational efficiency, and promote sustainability by compressing metal scrap into compact bales. Power Hydrotech offers high-performance, customizable metal baler machines that meet the specific needs of businesses across various industries. By investing in a metal baler machine from Power Hydrotech, you can optimize your waste management processes, reduce operational costs, and contribute to a more sustainable future.

For more information on our metal baler machines, please call us at +91 9726044442 or email us at sales@powerhydrotech.com. Let Power Hydrotech help you manage your metal waste more efficiently and effectively.