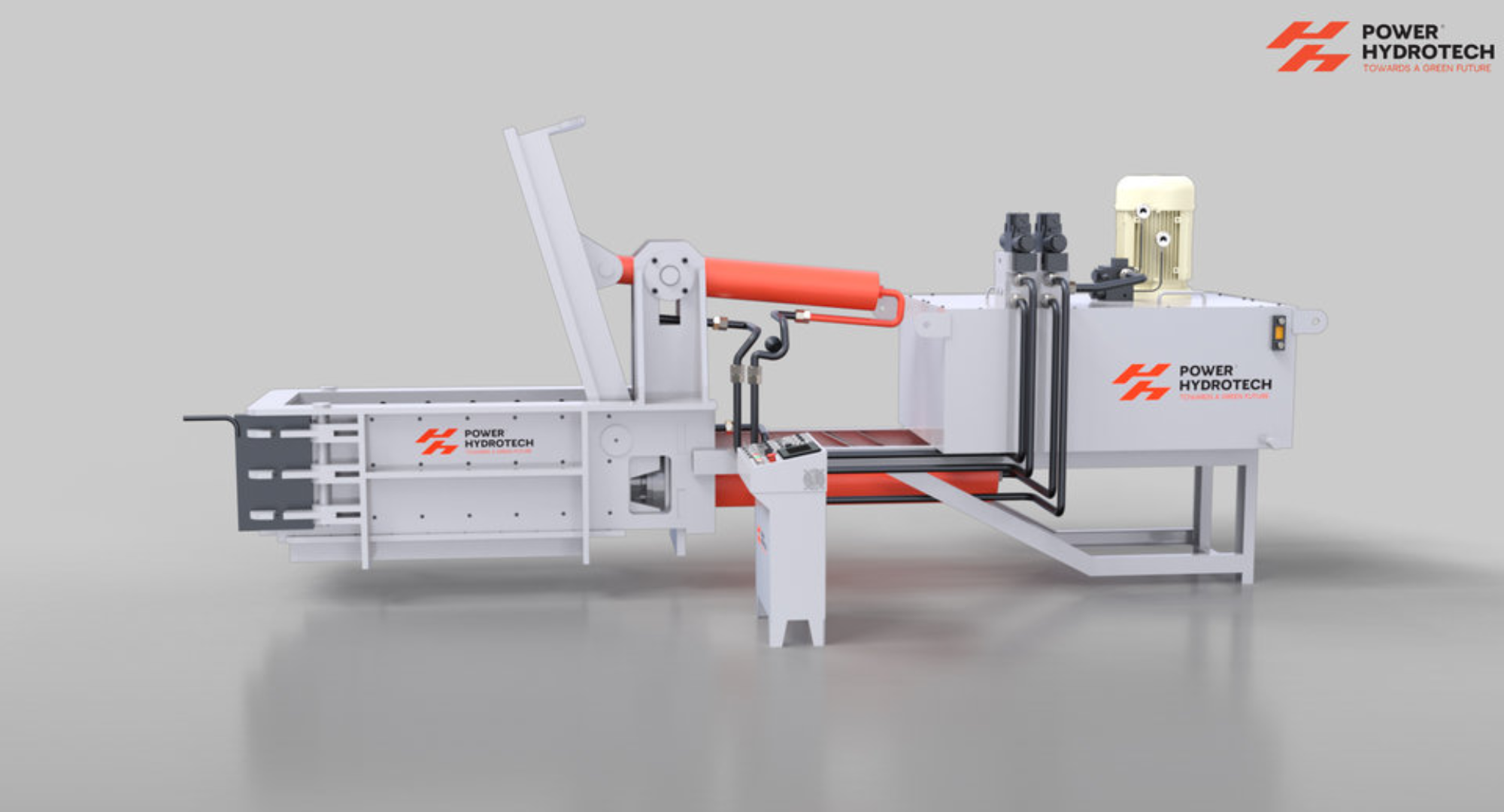

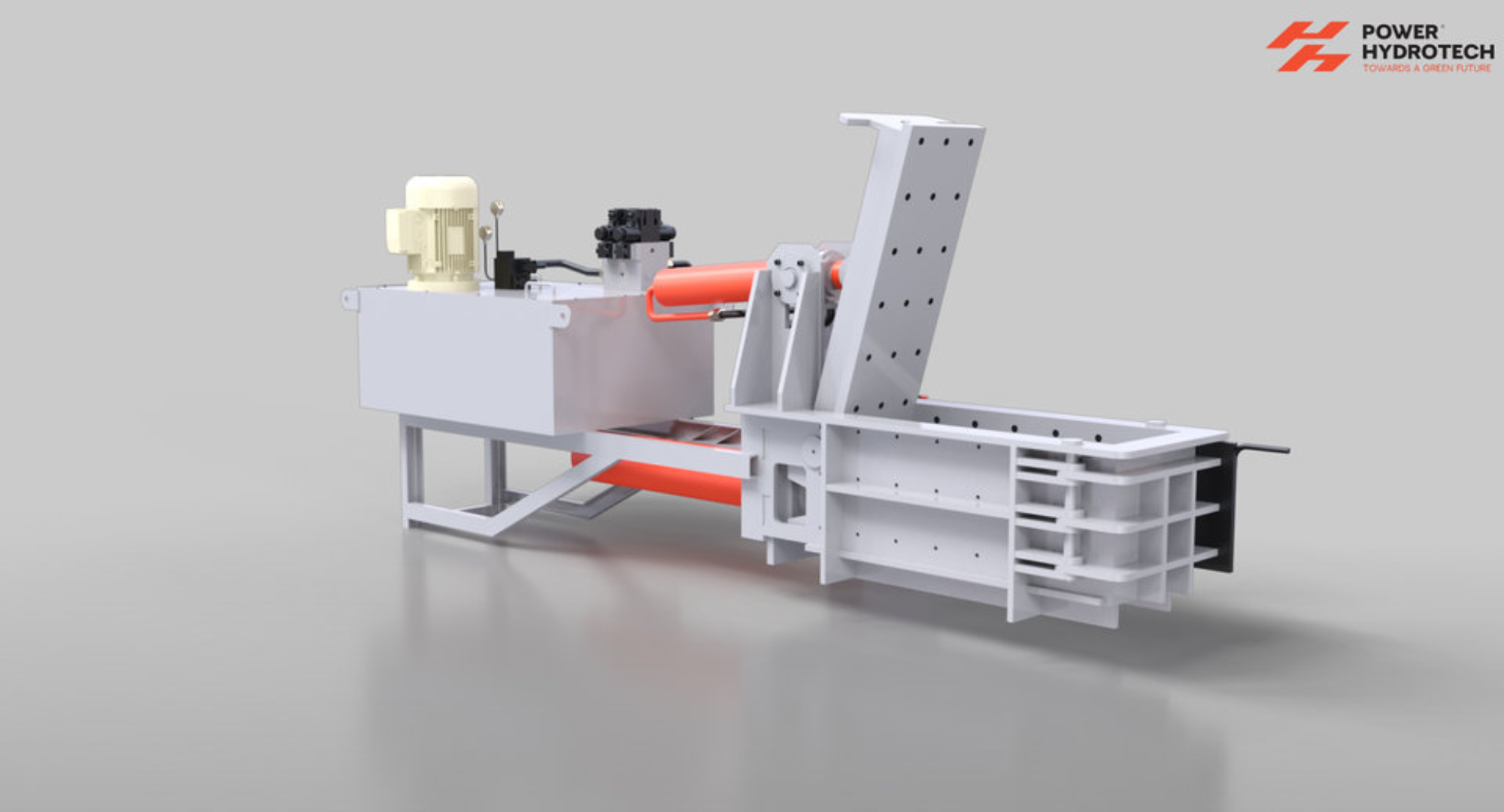

Double Action Baler

POWER HYDROTECH is the leading manufacturer and exporter of Double Action Baler in India. Our manufactured Double Action Baling Press are Demanding Product in the market for their high performance and low maintenance.

Suitable of Application for Double Action Baler

Our baling press machine suitable for, UBC can, stainless steel, copper aluminium scrap and a wide variety of materials such as steel cans, aluminum cans, wire, white goods, tubing, metal sheets, skeletons, aluminium coil scrap, aluminium tense scrap, alloy steel scrap, steel metal scrap, LMS scrap, CRC scrap, cast iron scrap, ferrous scrap, etc

Optional features :

- Feeding Hopper or Conveyor

- PLC Operation System

- Models available in Auto Door, Auto Eject (Front Eject, Side Eject)

- Oil Cooling

- They are only for illustration purposes and are subject to modify in accordance with the customer's requirements and technological improvements.

- Specifications are merely guidelines and may vary in response to client needs and technological improvements.

- All stated weights, dimensions, and cycle times are merely estimating.

- The type of scrap material the feeding rate, and the operator's skills all affect output