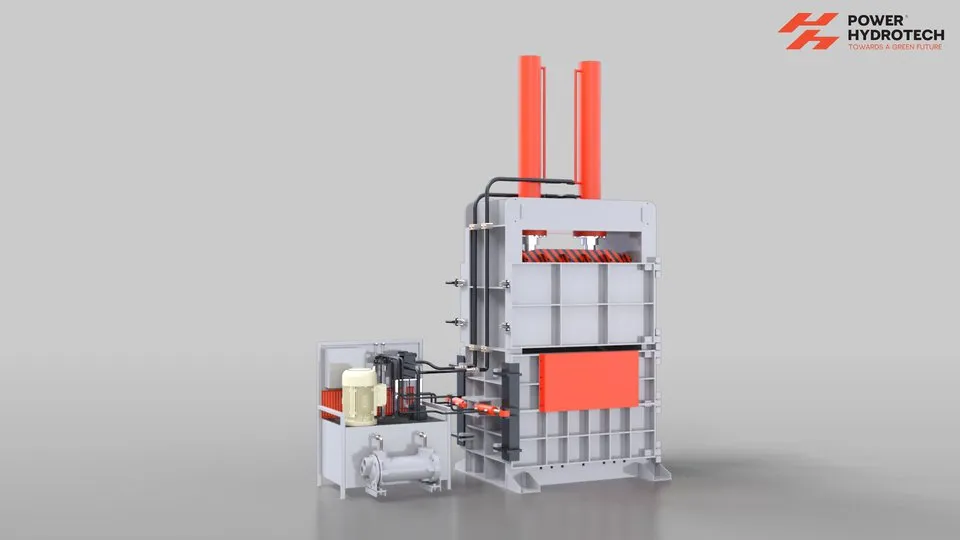

Power Hydrotech is a Leading Manufacturer of Waste Tyre Recycling Plant & Machine. In an age where sustainability is no longer optional, Tyre Recycling Plants are transforming the waste management landscape. Waste tyres, which once cluttered landfills and polluted the environment, are now being processed into reusable materials thanks to innovative technologies. At Power Hydrotech Pvt Ltd, we are leading this revolution with turnkey solutions that integrate high-performance Primary Shredders and Secondary Shredders, delivering unmatched efficiency in tyre processing. Our Tyre Recycling Plants are designed to convert waste tyres into high-value products such as rubber granules, recovered steel, and Tyre-Derived Fuel (TDF). These systems not only promote environmental sustainability but also present a profitable venture for industries looking to enter the recycling market.

How Modern Tyre Recycling Works

Advanced Tyre Recycling Plants follow a highly structured process to achieve optimal resource recovery. It begins with the Primary Shredder, which breaks down the tyres into smaller, manageable pieces. These are then passed through a Secondary Shredder, where they are further refined into uniform rubber chips. Magnetic separation systems extract the embedded steel wires, and sophisticated granulators help produce fine rubber granules for commercial use. The use of automation and sensor-based sorting enhances output quality and operational efficiency, making modern Tyre Recycling Plants a perfect fit for today’s eco-conscious industries.

Key Benefits of Tyre Recycling Plants

The advantages of investing in Tyre Recycling Plants are extensive:

- Waste Reduction: Diverts millions of tyres from landfills and open burning.

- Environmental Conservation: Limits soil, air, and water pollution.

- Resource Recovery: Generates valuable materials like rubber granules and steel.

- Energy Production: Tyre-Derived Fuel serves as an efficient and cleaner alternative to coal in cement and power plants.

- Economic Value: Opens new markets and revenue streams for recycled products.

These benefits make Tyre Recycling Plants a powerful tool in modern waste management strategies.

Applications Across Diverse Industries

One of the biggest strengths of Tyre Recycling Plants lies in their versatility. The outputs from these facilities are used in a broad range of sectors:

- Rubber Manufacturing & Reuse: Recycled rubber is used for making flooring, playground surfaces, and sports field turf.

- Construction Industry: Granules are mixed into modified asphalt, roofing materials, and even rubberized concrete for enhanced durability.

- Cement & Energy Plants: Tyre-Derived Fuel (TDF) replaces traditional fossil fuels, reducing emissions and lowering operational costs.

- Automotive & Plastic Recycling Units: Recycled rubber finds new life in molded vehicle components and plastic blends.

- Waste-to-Energy Initiatives: Tyres can be thermochemically converted into oil and gas through pyrolysis, contributing to energy recovery goals.

With such wide-ranging applications, Tyre Recycling Plants are fast becoming essential infrastructure for sustainable industrial development.

Tyre Recycling and Circular Economy

The role of Tyre Recycling Plants in the circular economy is undeniable. Instead of treating tyres as waste, these plants enable their transformation into raw materials that can re-enter the production cycle. This promotes resource efficiency, reduces extraction of virgin materials, and significantly lowers the carbon footprint of various industries. As a result, governments and corporations worldwide are actively supporting the development of Tyre Recycling Plants to align with climate and sustainability goals.

Global Demand and Market Trends

The global demand for Tyre Recycling Plants is increasing rapidly. With over a billion tyres discarded annually, the opportunity to convert waste into wealth has never been more promising. India is emerging as a hub for recycling innovation. As a leading Tyre Recycling Plants Manufacturer in India, Power Hydrotech is well-positioned to meet this growing demand with reliable and scalable solutions. Rising urbanization, regulatory pressures, and environmental awareness are fueling investments in Tyre Recycling Plants. Businesses that embrace this shift today are bound to reap both ecological and financial benefits in the future.

Why Choose Us

Power Hydrotech is committed to advancing waste management through reliable, efficient, and innovative recycling solutions. As a trusted Tyre Recycling Plant and Machine Manufacturer, we offer fully integrated systems tailored to specific client requirements. Our plants are engineered with precision, incorporating international safety standards, high-capacity shredders, and smart automation. We provide end-to-end support, from design consultation to installation and maintenance. By choosing Power Hydrotech, clients partner with a brand that prioritizes quality, sustainability, and long-term value creation.

Conclusion

With advanced technology and industry-specific customization, Tyre Recycling Plants offer a comprehensive solution to the global tyre waste crisis. They not only convert waste into valuable resources but also contribute to economic development and environmental health. Power Hydrotech Pvt Ltd, a leading Tyre Recycling Plants Manufacturer in India, continues to empower businesses with efficient, eco-friendly, and profitable tyre recycling systems. As we move toward a more sustainable future, investing in a Tyre Recycling Plant and Machine Manufacturer is a smart and responsible choice.

Interested in learning more about The Future of Waste Management: Benefits of Tyre Recycling Plants? Contact Power Hydrotech today. Call us at +91 9726044442 or email us at: sales@powerhydrotech.com Today!