How Lifting Chamber Baler Machines Revolutionize Textile Waste Handling

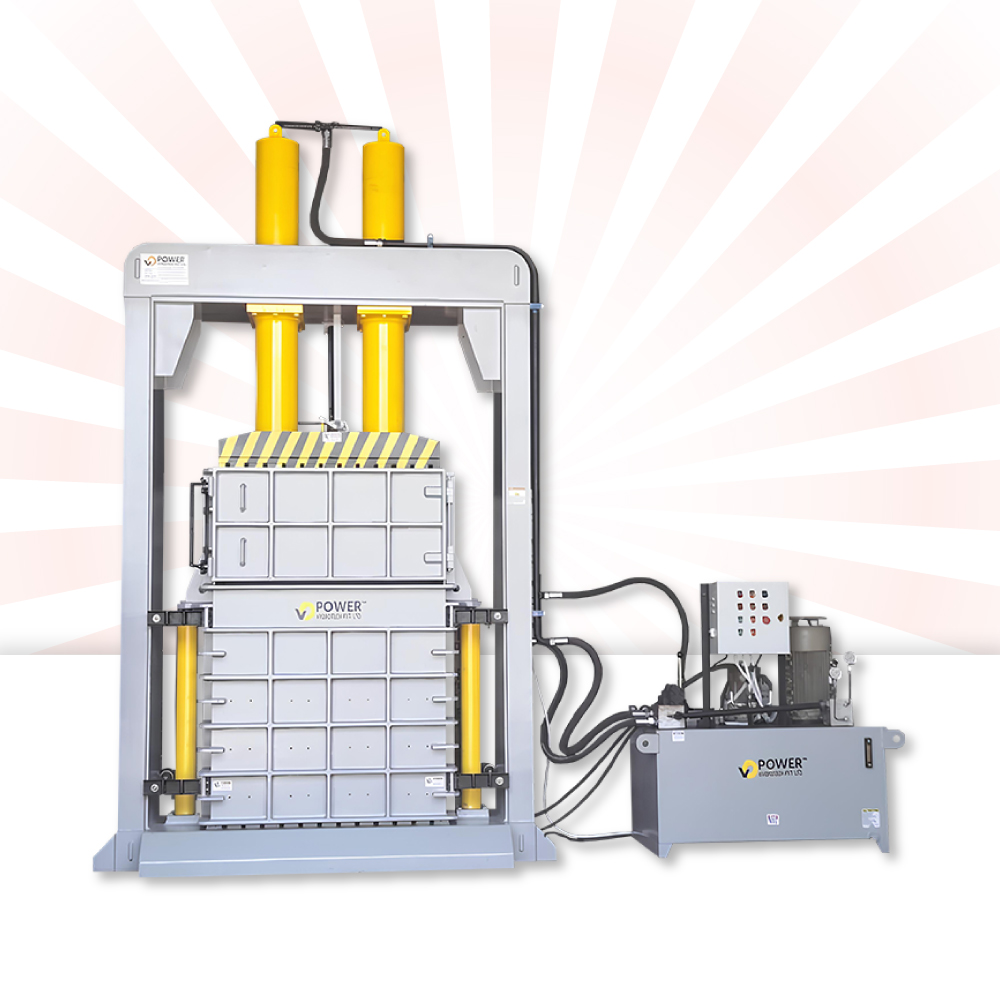

Power Hydrotech is a leading manufacturer and exporter of all types of waste cloth baler machines in India, including the highly efficient lifting chamber baler machines. The textile industry is one of the largest and most essential sectors in the global economy, known for its vast production of fabrics, garments, and textiles. However, as the production of textiles increases, so does the amount of waste generated. From leftover fabric scraps to used clothing and raw materials, managing textile waste is a significant challenge. One of the most effective solutions to this challenge is the use of a lifting chamber baler machine, which plays a critical role in compressing waste textiles into compact bales for easier storage, handling, and transportation.

These machines are in high demand across industries due to their impressive performance and low maintenance requirements. Whether it is waste cloth, cotton waste, coir fiber, or any other textile by-product, lifting chamber baler machines are designed to handle a variety of materials efficiently, making sure better waste management and optimized space utilization in manufacturing units and textile plants. In this, we’ll explore how lifting chamber baler machines work, the importance of these machines in the textile industry, and why Power Hydrotech’s baler machines are the preferred choice for businesses involved in textile waste management.

What Is a Lifting Chamber Baler Machine?

A lifting chamber baler machine is a specialized piece of equipment used in the textile industry to compress waste materials such as cotton waste, fabric scraps, coir fiber, and other textile by-products into compact bales. These bales are easier to store, transport, and recycle, helping to reduce waste accumulation and improve operational efficiency.

The primary feature that distinguishes lifting chamber balers from other types of balers is their lifting mechanism. This mechanism allows the waste material to be fed into the chamber and compressed vertically, enabling the formation of a tightly bound bale. The machine is designed to handle various materials, and depending on the configuration, it can accommodate a range of textile waste products, including cotton, jute, coir, thread, and more. The compact design of the lifting chamber baler makes it suitable for textile industries that need to process significant amounts of textile waste without taking up too much space. The baling process is quick and efficient, allowing businesses to manage their waste effectively while maintaining a clean and organized work environment.

How Does a Lifting Chamber Baler Machine Work?

The operation of a lifting chamber baler machine is straightforward yet highly effective. Here’s how it works:

- Feeding the Material: The textile waste, which could include fabric scraps, cotton waste, or other materials, is fed into the lifting chamber of the baler. This can be done manually or with the assistance of a conveyor system, depending on the setup.

- Compression: The machine’s hydraulic system activates, applying force to compress the waste material. The lifting chamber mechanism allows the material to be lifted into the chamber where it is compacted into a tightly bound bale. The hydraulic pressure is applied uniformly to ensure consistency and efficiency in the compression process.

- Bale Ejection: Once the material is fully compressed into the desired shape and size, the machine ejects the compacted bale. These bales are then securely tied using wire or other materials to hold them together.

- Storage and Transport: The bales are ready for storage or transportation. The compacted form of the material makes it easier to stack, store, and move to recycling facilities or other processing units. This also helps save on storage space and reduces the overall volume of textile waste.

Key Benefits of Lifting Chamber Baler Machines in the Textile Industry

The adoption of lifting chamber baler machines in the textile industry offers several key benefits that improve efficiency and waste management processes:

- Improved Space Utilization

One of the primary advantages of lifting chamber baler machines is their ability to save space. Textile production and processing often generate large amounts of waste, which can accumulate quickly and take up valuable floor space. By compressing textile waste into compact bales, these machines reduce the volume of waste, allowing businesses to make better use of their available space. - Improved Efficiency

The lifting chamber baler machine is designed for high efficiency, ensuring that waste is processed quickly and consistently. The machine can handle a wide variety of materials, making it ideal for industries that generate different types of textile waste. By automating the baling process, businesses can reduce the need for manual labor, leading to faster operations and increased productivity. - Reduced Transportation Costs

Compressed bales are much easier to handle and transport compared to loose, uncompressed waste materials. Lifting chamber baler machines compact waste into tightly bound bales, which can be stacked and transported more efficiently. This not only reduces the space required for storage but also lowers transportation costs, as fewer trips are needed to dispose of or recycle the waste. - Lower Maintenance Requirements

Power Hydrotech’s lifting chamber baler machines are known for their durability and low maintenance requirements. The machines are designed with strong components and are built to withstand the demands of daily use in the textile industry. The advanced hydraulic systems used in these balers require minimal upkeep, reducing downtime and operational costs for businesses. - Contribution to Sustainability

With sustainability becoming increasingly important in today’s world, the textile industry is under pressure to reduce its environmental impact. Lifting chamber baler machines play an important role in recycling efforts by compressing waste materials, making them easier to transport to recycling centers. This helps reduce the amount of textile waste that ends up in landfills, contributing to the circular economy and promoting environmental conservation.

Applications of Lifting Chamber Baler Machines in the Textile Industry

Lifting chamber baler machines are capable and can be used in various sectors within the textile industry. Some common applications include:

- Textile Waste Recycling

Textile waste recycling is one of the most important applications of lifting chamber baler machines. The machine helps compress fabric scraps, cotton waste, and other materials into bales that can be sent to recycling centers. This process ensures that waste is repurposed, either as raw material for new products or as fabric for new textiles. - Cotton Waste Management

In cotton processing plants, cotton waste is a by-product of the manufacturing process. A lifting chamber baler machine can effectively handle cotton waste, compacting it into bales that are easier to store and transport. These bales can be sent to recycling facilities or used in other industries that require cotton-based raw materials. - Coir Fiber Processing

Coir fiber, derived from coconut husks, is another material that can be processed using lifting chamber baler machines. The machine compresses coir fiber into bales that are easier to handle and transport. This is particularly useful in industries where coir is used in products like mats, ropes, and mattresses. - Textile Manufacturing Plants

In textile manufacturing plants, large quantities of fabric scraps, threads, and waste are generated during production. Lifting chamber baler machines are used to compress these materials into bales, helping to maintain a clean work environment and optimize waste management.

Why Choose Power Hydrotech’s Lifting Chamber Baler Machines?

As a trusted name in the manufacturing of lifting chamber baler machines, Power Hydrotech stands out for several reasons:

- High-Performance Machines

Power Hydrotech’s lifting chamber baler machines are engineered for high performance. These machines offer quick, consistent, and reliable baling, helping businesses improve productivity and reduce waste management costs. - Durability and Reliability

Our lifting chamber baler machines are built to last. The strong construction ensures that the machines can handle heavy-duty operations and provide long-term reliability, minimizing the need for frequent repairs and downtime. - Customized Solutions

We understand that every business has unique needs, which is why we offer customizable solutions. Whether you need a baler for cotton waste, textile scraps, or other materials, we can provide a machine tailored to your specific requirements. - Expert Support

At Power Hydrotech, we believe in providing excellent customer support. Our team of experts is always ready to assist with machine installation, maintenance, and troubleshooting, ensuring that you get the most out of your lifting chamber baler machine.

Conclusion

In the textile industry, where managing waste efficiently is important for both operational success and sustainability, lifting chamber baler machines have become an indispensable tool. These machines offer several benefits, including improved space utilization, higher efficiency, and reduced transportation costs. Power Hydrotech’s lifting chamber baler machines are engineered to deliver maximum performance while maintaining low maintenance, making them the ideal choice for businesses involved in textile waste management.

For more information on how lifting chamber baler machines can help streamline your waste management processes, call us at +91 9726044442 or email us at sales@powerhydrotech.com. Let us help you find the right solution to improve your operations and contribute to a more sustainable future.